A crop optimization system for shear control in steel applications is a software or hardware system that is used to optimize the cutting process in the steel industry. This system uses advanced algorithms to control the cutting process and minimize the amount of scrap material produced during the manufacturing process.

The system works by analyzing the characteristics of the steel being cut and adjusting the cutting parameters to achieve the optimal cut. This includes adjusting the shear force, speed, and blade angle to ensure that the steel is cut cleanly and efficiently.

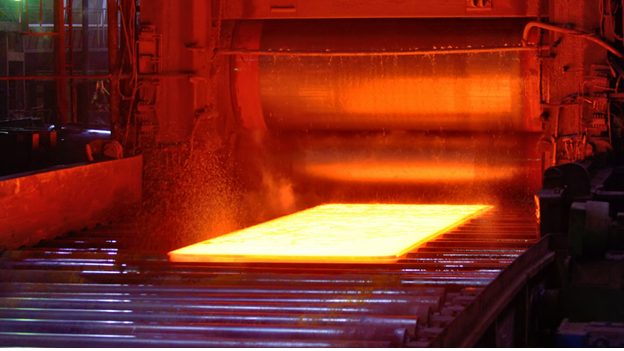

Crop optimization systems can be used in a variety of steel applications, including sheet metal production, plate cutting, and coil processing. They are particularly useful in applications where high volumes of steel are being processed, as they can help to reduce waste and increase productivity.

Global Gauge’s solution for Crop Optimization uses an Allen-Bradley ControlLogix PLC, and can interface with existing Hot Metal Detectors at customer facilities. Additionally, GGC can offer an analytics package which creates the ability to view, archive, and analyze images of the entire length of the material.

Overall, a crop optimization system for shear control in steel applications is an important tool for manufacturers looking to improve the efficiency and profitability of their operations, and Global Gauge is a top-tier supplier of crop optimization systems that help you make better steel and more profits.