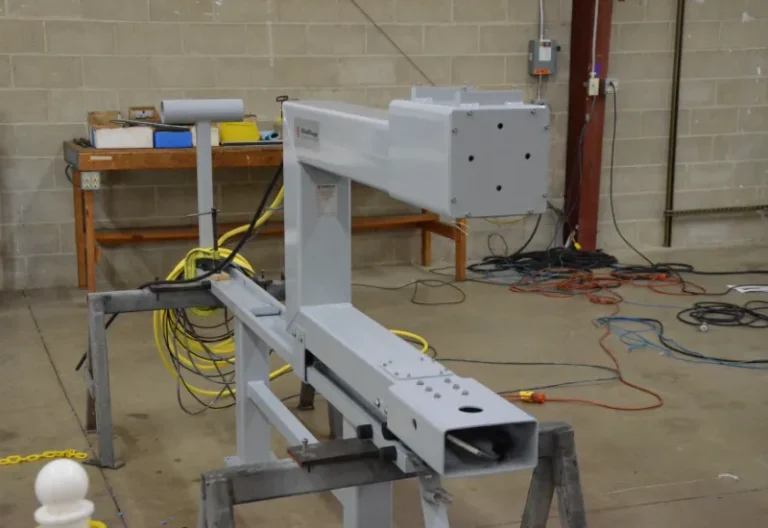

Perfecta Thickness Gauge

The Industry Standard In PLC-Based Gauging

Perfecta Thickness Gauge

Responsible | Dependable | Accurate | Cost-Effective

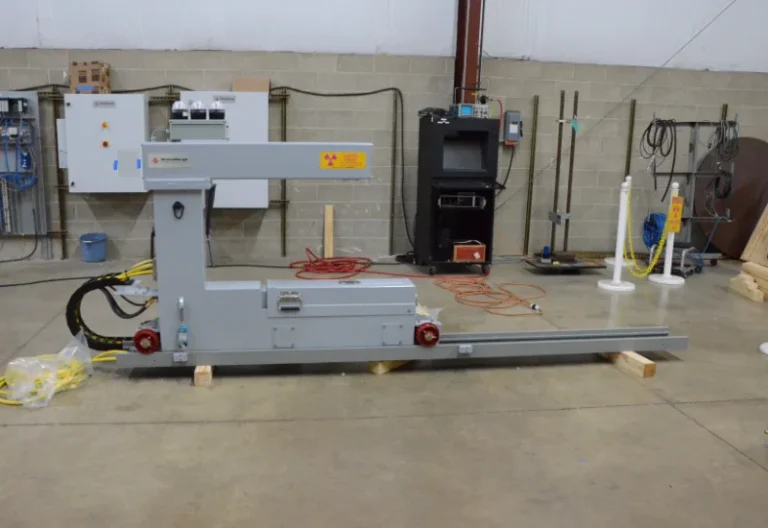

The Perfecta Gauge is the “original” PLC-based Thickness Gauge System. From the first installation in the late 90s, Perfecta customers have enjoyed the benefits delivered by the high reliability of the PLC. This system can be built from Allen Bradley, General Electric, Siemens, or Modicon PLCs (others available also). All critical gauge functions run through the PLC. A PC is usually included to act as the HMI device, but if the PC locks up for any reason, the gauge continues to function. Low cost of ownership is achieved due to the fact that many of the gauge components are off-the-shelf. Perfecta Gauges are installed all over the world in rolling mill applications.

Why Choose the Perfecta Thickness Gauge?

Rugged, Mill-Duty Enclosure

Engineered to withstand extreme mill environment with high durability.

Industry Proven Performance

Relied upon leading manufacturers for consistent precision.

Seamless Automation

Integrates with leading PLC/SCADA systems like Siemens & Allen-Bradley.

High Speed

Precision

Industry-proven performance for high-speed precision

Flat Rolled Metals

Designed specifically for precision in flat-rolled metals production lines.

Increase Product Quality

Real-time thickness control ensures consistent high quality output.

Minimize Scrap

Accurate gauging means less material waste, saving time and cost.

Optimize Line Efficiency

Enables uninterrupted production with inline measurement.

Perfecta Thickness Gauge Specifications

MEAN RESPONSE TIME

The mean time after a step variation in the measured quantity until the output signal reaches a specified percentage of its final mean value for the first time. For this standard, 63.2% of the step change shall be the specified percentage.” (IEC 1336, 1.3.24.1)

Response Time

<2mS per Test Point A (IEC 1336, 1.3.7.1)

STATISTICAL NOISE

Variation of the output signal under reference conditions, while all influence quantities are held constant and the detector is in an irradiated condition.” (IEC 1336, 1.3.22)

Statistical Noise @10mS the 2σ variation = ± 0.12%

ACCURACY

Degree of conformity of an indicated value to a recognized standard value, or ideal value.” (IEC 1336, 1.3.14)

In the case of Thickness Gauges, the standard value is usually a precision master (internal or external) on which the gauge has been standardized. Accuracy is usually expressed as a percentage of the nominal thickness being measured.

Accuracy The accuracy 2σ = ± 0.1%, not better than ± 0.2μm

DRIFT

Drift is expressed as a percentage of the nominal thickness being measured.

Short Term ~1 hour ≤ ± 0.05% from the set thickness, not better than ± 1μm

Long Term ~8 hours ≤ ± 0.1% from the set thickness, not better than ± 2μm

REPRODUCIBILITY

Closeness of agreement among a number of consecutive measurements of the gauge output signal for the same input and under the same operating conditions.” (IEC 1336, 1.3.15)

Reproducibility ≤ ± 0.1% from the set thickness, not better than ± 5μm

Repeatability ≤ ± 0.05% from the set thickness, not better than ± 1μm

LINEARITY

The closeness to which the actual calibration curve approximates a straight line.” (IEC 1336, 1.3.26)

Linearity ≤ ± 0.05% from the set thickness, not better than ± 1μm

Perfecta Thickness Gauge Gallery

You May Also Be Interested In

Contact Us Today

With our partners in Europe and Asia, we have a worldwide reach. We provide the complete system engineering, design, fabrication, and installation – along with knowledgeable service and availability when you need us, regardless of your spot on the globe. Let us show you how we can help with your gauge needs.