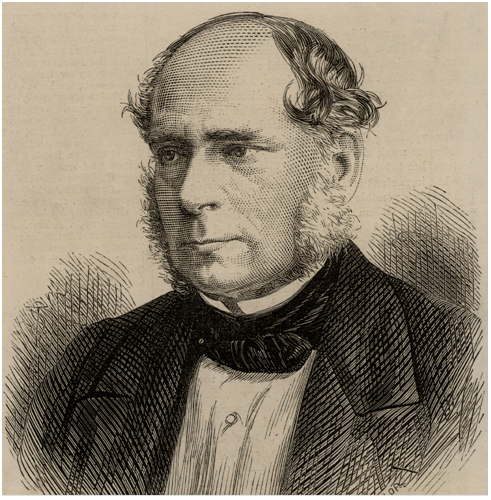

Henry Bessemer

The history of the steel industry is a chronicle of human innovation and industrial growth that stretches back thousands of years. From its rudimentary beginnings in early civilizations to the monumental strides during the Industrial Revolution, the development of steel has played a crucial role in shaping our world.

The initial discovery of iron and its production is attributed to the Hittites around 2000 BC, but the secrets of steel production remained mostly undiscovered for centuries. The iron produced in these early periods lacked the durability and strength that characterize steel, due to its low carbon content.

In the 17th century, the carburization process was developed, where iron was heated in the presence of carbon-rich substances like charcoal. This process increased the hardness of iron, but it was inconsistent and not suitable for mass production, and so its use was limited.

The most significant leap in the steel industry occurred in the 19th century during the Industrial Revolution, thanks to Sir Henry Bessemer. Bessemer introduced a revolutionary process in 1856 that fundamentally transformed the steel industry.

The Bessemer Process, named after its creator, was an innovative method that allowed for the efficient and cost-effective mass production of steel. The process began by melting pig iron in a furnace known as a ‘converter.’ Once the iron reached a molten state, air was blown through the bottom of the converter. The air oxidized the impurities, such as silicon and manganese, converting them into slag which was lighter and floated on the molten iron for easy removal.

The primary challenge of this method was controlling the amount of carbon left in the steel. Too much carbon, and the steel would be too hard and brittle. Too little, and it would be softer and weaker. By carefully monitoring the color and temperature of the flame exiting the converter, operators could estimate the carbon content and stop the process at the desired level.

This process was a significant upgrade from the previous iron materials used in construction and other industries. Steel was more durable, stronger, and could resist higher stress levels than cast iron or wrought iron. However, the Bessemer Process had its limitations. It struggled to remove phosphorus, a common impurity in iron ore, which could lead to brittle steel.

This limitation was overcome by Sidney Gilchrist Thomas in the late 19th century. Thomas added limestone to the Bessemer converter, which reacted with the phosphorus to form slag that could be easily separated from the molten iron.

The 20th century brought further improvements to the steelmaking process. The Basic Oxygen Steelmaking process (BOS), introduced in the 1950s, was even more efficient than the Bessemer Process. Instead of blowing air through molten pig iron, the BOS process used pure oxygen, which sped up production and reduced impurities.

Today, steel’s strength, durability, and versatility, coupled with the ability to produce it on a large scale, make it indispensable across industries. From skyscrapers to bridges, vehicles to household appliances, steel’s influence is evident in every facet of modern life. The evolution of the steel industry, particularly the breakthrough of the Bessemer Process, has undeniably shaped the trajectory of industrial and technological development worldwide.