The Width Gauge

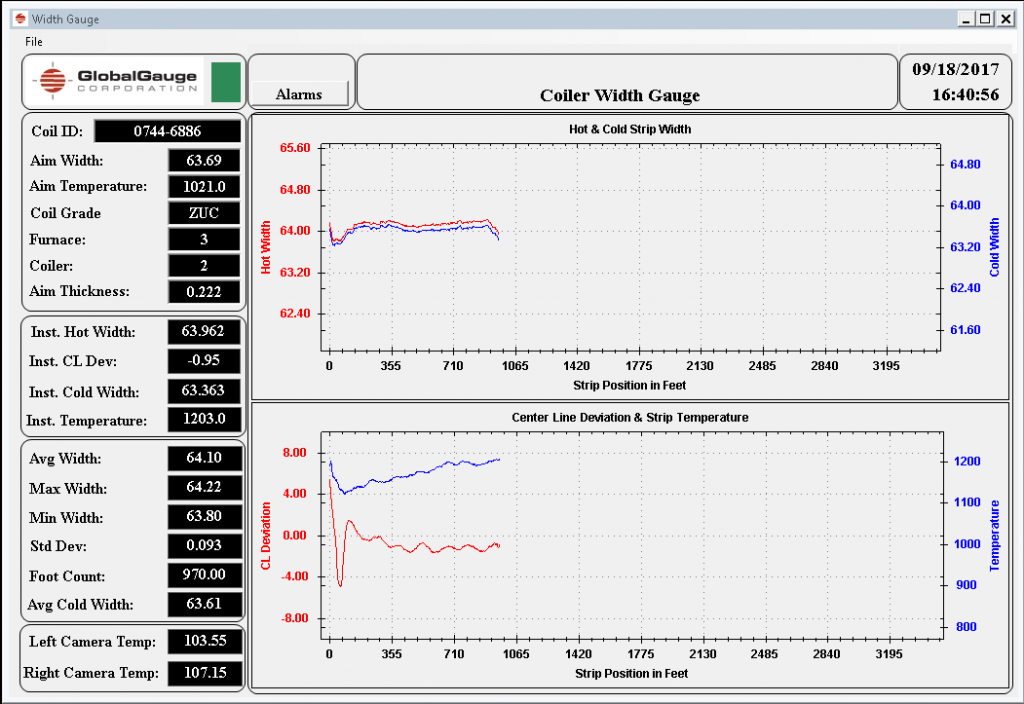

The Global Gauge Width Gauge is a precision measurement device used to determine the width of sheet or strip products in hot or cold mill applications. Digital lines-can cameras capture images of the edges of the material. Image data is transmitted from the cameras to the processor via fiber-optic cable or equivalent, thus eliminating image corruption issues inherent in older analog systems. Data is processed in a server-grade PC resulting in width and centerline deviation data being instantly displayed on the operator’s panel. Our width gauges are enclosed in a robust environmental housing, specifically designed for the harsh environment of a rolling mill. Our width gauges are extremely accurate, highly reliable, and very easy to install and use.

Our width gauges are arranged to optimize the customers’ application. In many cases, a single camera assembly will suffice for customer needs, however we can also arrange our cameras in a dual-camera setup, or a stereoscopic manner (to account for depth of field view and further increase accuracy).

Global Gauge is capable of manufacturing width gauges that are customized for our customers’ specific needs.

Width gauges can be optimized for the following applications:

– Hot Mills

– Cold Mills

– Plate Mills

– Process Lines

– Post-Slit Multi Measurement

Full Profile Dimensional Measurement

GGC Width Gauges furthermore can be optimized to provide customers with full 2D profile measurements and store images, which can be especially useful in plate and bar mills. Using the same fundamental imaging principles of the GGC width gauge, our dimensional measurement systems can additionally allow our customers to accurately measure camber, squareness, and length of their material. All of the image from the material can be stored on the server-grade PC provided with the system, or uploaded to the customers’ network in real time.

Vision Systems with Analytics Packages

Global Gauge Vision Solutions are often incorporated into our Width Gauge applications for various analytical purposes. However, we have also installed stand-alone analytical Vision Solutions.

Our various vision applications include, but are not limited to: – Gross Defect Detection Down to 1mm Defect Size – Crop Optimization – Shear Control Systems Resulting from Crop Optimization Measurement – Thermal Profile Analysis for Red-hot Applications – Complete Bar Imaging – Head/Tail Imaging – Hook Detection – Edge Crack Detection – Crop Drop Indication

We are always looking for new ways to assist our customer with custom vision systems, and expect that we will continue to find creative and innovative ways to use our technology to help our customers learn more about their products and processes.

All of our systems are manufactured and assembled at our facility in Moraine, OH. Global Gauge Width Gauges and Vision Solutions are extremely reliable and dependable, and our service is the best in the industry, as evidenced by our 24/7/365 service hotline.

Always Made in America and Respected Worldwide