Applications for Powdered Metals & Ceramics

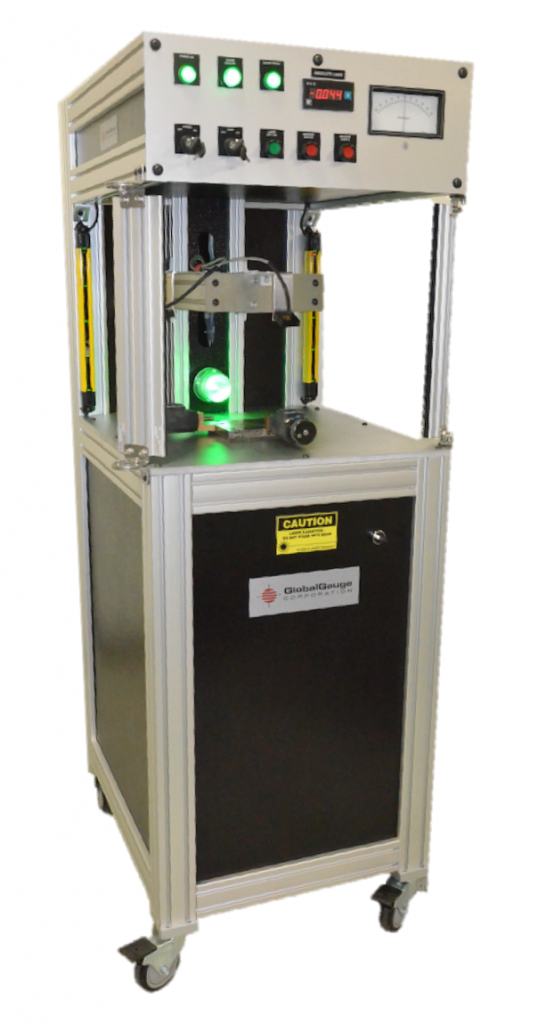

In 2015, Global Gauge Corporation introduced the Density Comparator to the ceramics and powdered metals industries.

The most critical stage of the manufacturing process of high-tech ceramics and powdered metals is sintering. Global Gauge adds certainty to this process, saving our customers material, time, and money.

Prior to sintering, pre-mixed powdered metal and binding materials are inserted into a die before being uniaxially-pressed. This pressing process lightly fuses the materials together into a semi-solid shape , roughly resembling the shape and dimensions of the final product.

Global Gauge has developed an x-ray based “Density Comparator” to specifically serve this industry. Installed in powdered metals plants around the globe, our systems allow customers to check the relative density of a part after being pressed — but prior to sintering. These “green density” checks allow our customers to know for certain whether the part is within their density variation tolerances, and determine if there will be significant warping resulting from the sintering process. Typical parts we analyze are ceramic gears, flanges, bearings, and various other components in automotive, aerospace, semi-conductor, and other high-tech industries.

VIDEO: The Global Gauge Density Comparator

If the Density Comparator indicates that there are density variations outside of the allowable range, the press operators can quickly make the appropriate changes to their presses to ensure the part falls within the pre-sintered tolerances, without having to scrap an entire batch of products.

The Density Comparator removes an enormous bottleneck in traditional powdered metals and ceramics manufacturing, as our customers can be certain of their green density uniformity prior to sintering, and decrease material waste, increase efficiency, and — above all — save money.