Global Gauge Build The World’s Best X-Ray Thickness Gauges Coating Weight Gauges And Width Gauges

From raw materials to finished products, measuring the thickness, width, and coating weight of steel or other metals (such as aluminum) has become one of the most effective methods of maximizing your process’ efficiency and quality, while maximizing yield wherever possible. Whether you are a steelmaker using a blast furnace or an electric arc furnace (EAF), or a small slitting or cut-to-length operation, process instrumentation and automation are essential to meeting your customers’ demands.

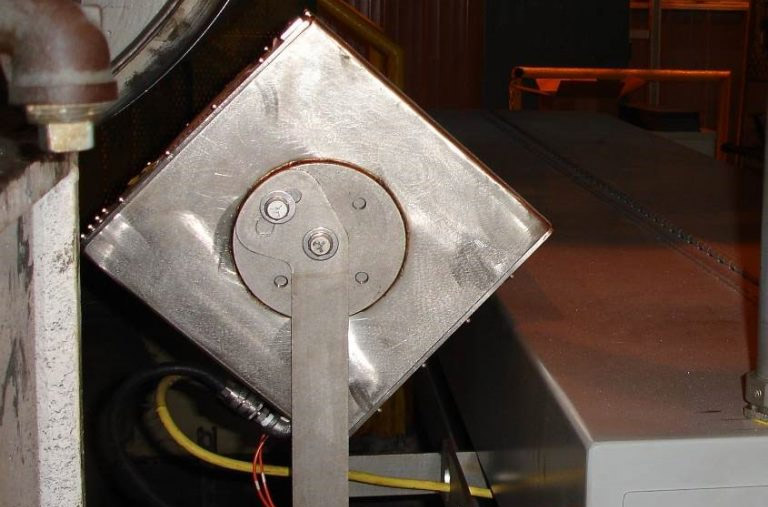

As the largest USA-based supplier of X-ray Thickness gauges, Global Gauge is recognized as the industry standard for non-contact thickness measurement systems for rolling mills and process lines.

We provide custom solutions to all of our customers, delivering millisecond-level response time and over 99.99% accuracy. We also provide alloy compensation for specialty metals such as aluminum or other alloys. We offer a variety of measurement setup options: typical gauge setups are center-line, traversing, multi-point, or any combination of the three.

All of our sensors and gauges are manufactured and assembled at our facility in Moraine, OH.

You can count on our service to be prompt and reliable, as evidenced by our 24/7/365 service availability. Our gauges are extremely reliable and dependable, and our service is the best in the industry.

Made in America. Respected Worldwide.