In today’s Steel Industry, global competition along with rising costs have made maximizing yield vital to the success of manufacturers. Steel manufacturers should be focusing on maximizing yield in every process of steel making and to optimize their yield, they need to measure their outputs. With regard to steel coating, manufacturers in particular try to maximize yield by avoiding “over-coating” the steel substrate in galvanizing, galvalume, aluminizing, or tin-coating processes. “Over-coating” unnecessarily wastes raw materials and increases the manufacturers’ overall cost.

For years, galvanizing, aluminizing, electrolytic tinning, and other hot metal coating lines have struggled to control the degree to which their processes over-coat. Stringent quality requirements make it imperative for manufacturers to meet minimum coating weight specifications. Not meeting the minimum specifications results in rejected and scrapped material. Material that is “under-coated” and which makes its way out into the market is subject to corrosion, reducing the life span of the material. In an attempt to account for this concern, manufacturers tend to over-coat to ensure minimum specifications are met and their customers remain satisfied.

In order to reduce the amount of over-coating, forward-thinking manufacturers continue to rely on Coating Weight Gauges for measurement and optimization of their coating output. Coating Weight Gauges use x-ray technology to precisely measure the amount of galvanized, galvalume, aluminized, or tin coating on a substrate. Coating Weight Gauges provide real time feedback data for operators to understand their current rate of coatings, and make quick coating weight adjustments during production. Coating Weight Gauges are extremely accurate providing both top and bottom side scanning measurements. This allows the manufacturer to provide uniform coating that meets quality specifications and satisfies their customer requirements, all the while maximizing yield.

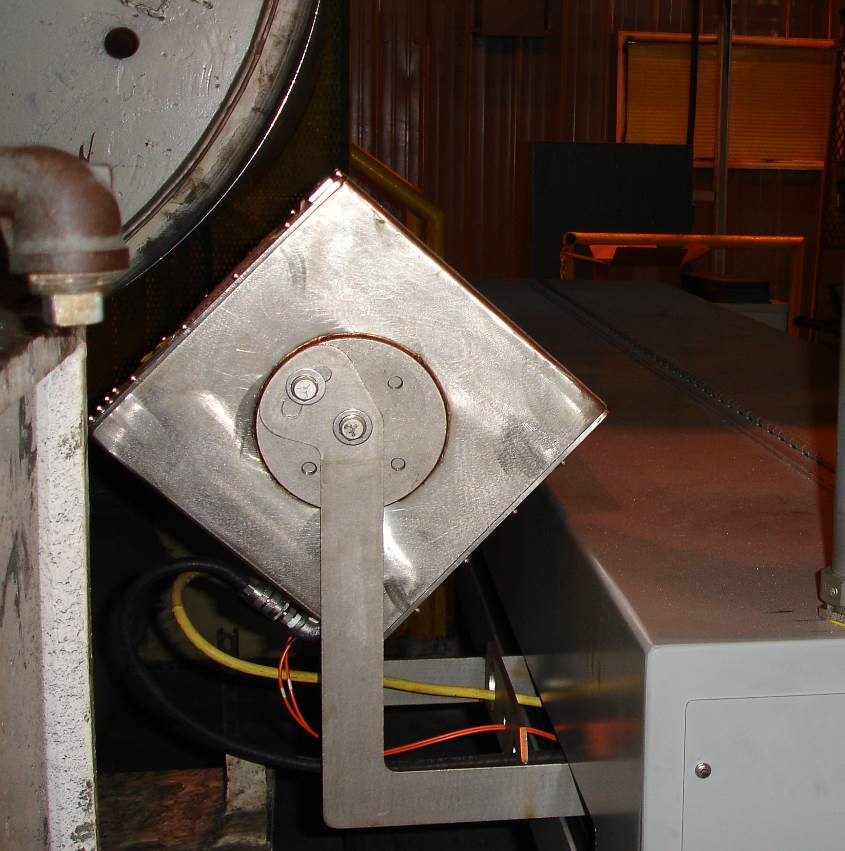

Global Gauge’s Coating Weight Gauging system is capable of measuring various metallic coatings such as zinc, tin, aluminum, and other hot metals coatings. The principle of operation is to direct an x-ray beam into the coated material, with enough energy level sufficient to fluoresce the steel substrate under the coating. By detecting and measuring the intensity of the “backscattered” radiation, the thickness of the coating can be accurately determined to a remarkably high degree.

The Global Gauge Coating Weight Gauging system contains dual, next generation digital heads that are light-weight, using fiber optic cables for communications. Communications, HMI, and all other software characteristics can be customized per our customer requirements. Large cable bundles are eliminated. The Global Gauge Coating Weight Gauge – as is the case with every one of our gauging systems – is extremely accurate, cost effective, and dependable. Global Gauge can provide the complete system engineering, design, fabrication, and installation-along with knowledgeable service and availability when you need it. And we continue to manufacture and service all of our systems from the USA.

As always, you can count on our service to be prompt and reliable, as evidenced by our 24/7/365 service availability. Our gauges are extremely reliable and dependable, and our service is the best in the industry.

Made in America. Respected Worldwide.